In what’s perhaps the most unexpected collaboration of the year, Ford recently announced that for the past two years it has been working with Heinz on a way to turn waste from the two tons of tomatoes the ketchup maker uses every year into the world’s latest bioplastic.

Ford is no stranger to using plant-based materials in their cars. In fact it currently uses cellulose fiber-reinforced console components, rice hull-filled electrical cowl brackets, soy foam seat cushions and head restraints, recycled cotton material for seat fabrics and carpeting, and fiber composites made from coconut, wheat straw, kenaf and hemp. And while we’ve been keeping up to date with innovative biowaste and bioplastic prototypes, this is the first time we’re seeing a major car company and food producer work together to turn leftover tomato stems, seeds, and skins into a promising alternative to petrochemicals.

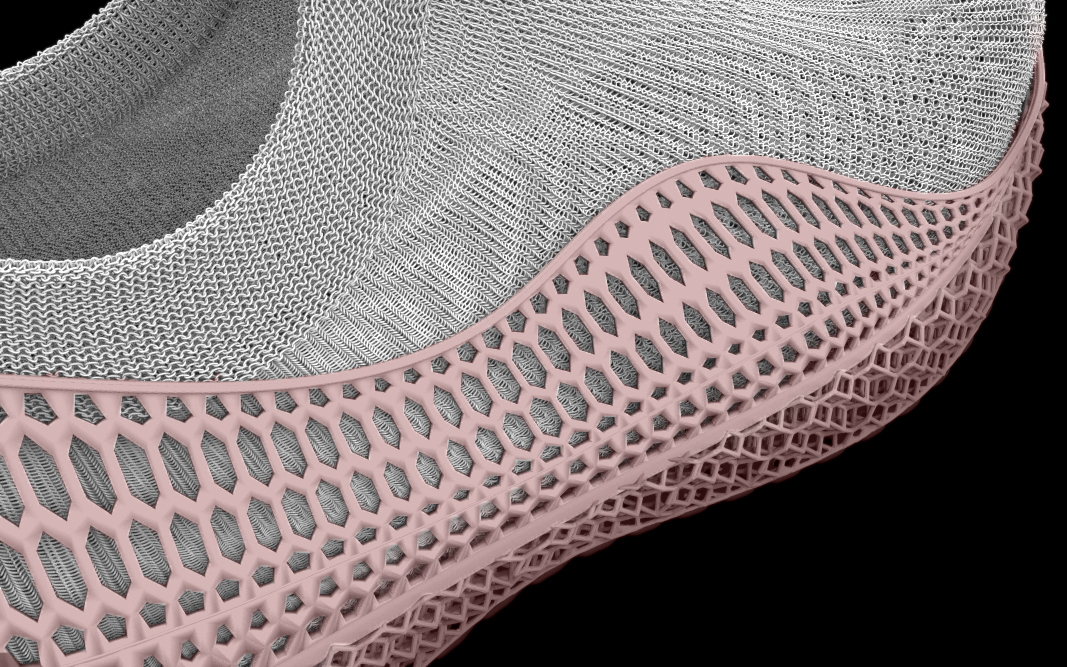

So far Ford is looking into tomato-fiber composites for interior trims and accessories like cup holders and brackets (not exterior structural parts), and the fact they can be made cheaper, faster, and at lower temperatures than their petrochemical counterparts has attracted interest from other major manufactures like Nike, Coca-Cola, and Procter & Gamble. No, we probably won’t see a tomato-based running shoe anytime soon, but it might not be long before Heinz’s leftovers are used to make the shoe box your next pair of sneakers comes in.

via Stylus. Image courtesy of themotorreport.au.