Each year, we eagerly track the finalists competing in MoMA PS1’s Young Architect’s Program, which has been (at least partially) responsible for launching the careers of talents such as SHoP, Interboro Partners, HWKN, WORK, nARCHITECTS, William E. Massie, and now The Living, an exciting firm that’s creating some of the most fascinating new projects with a focus on biocomputation and revolutionary new materials. And when we discovered that founder and principal David Benjamin had figured out a way to use biowaste from cornstalks and mushrooms as the sole ingredients in the 100% recyclable bricks that make up the towering Hy-Fi pavilion (which you can party under all summer long, from June 5 – September 5, 2014), we knew we needed to talk to him and find out how he did it.

Benjamin brought us into his studio at the Brooklyn Navy Yard and walked us through the process, making it sound as easy as baking a cake. (Full disclosure: it’s much harder than baking cakes.)

1. Grab a big bag of agricultural byproduct, in this case chopped up cornstalks. And yes, this is local agricultural byproduct, sourced from less than 150 away. “It’s a part of agriculture that would normally go to waste, so we’re making something out of nothing, almost,” Benjamin says.

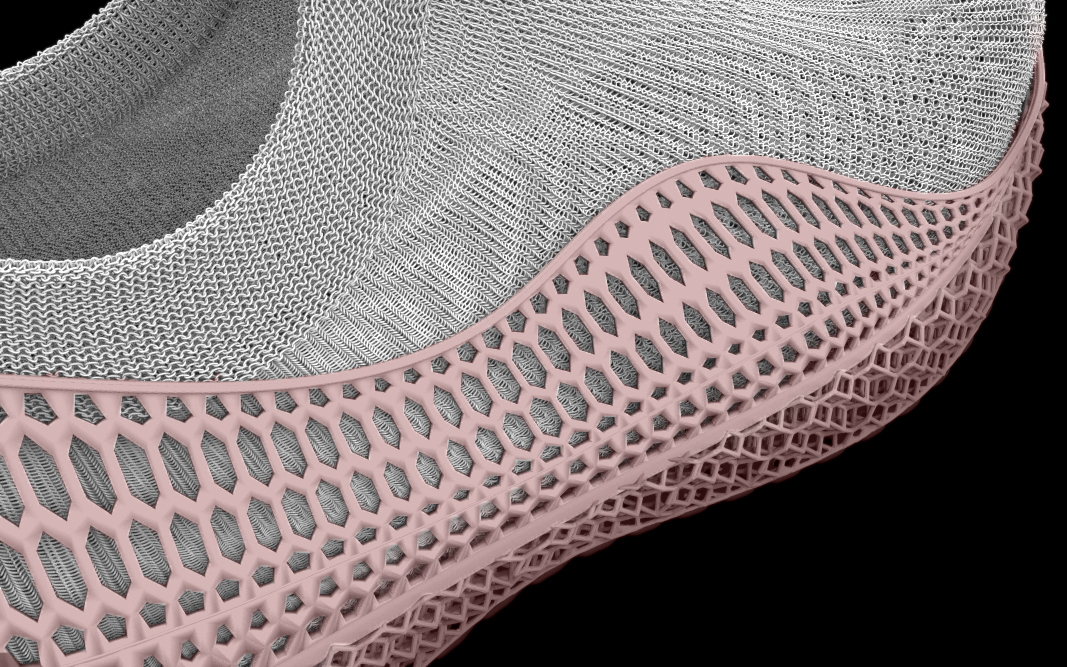

2. Outsource the brick-making (we prefer Ecovative) and take the rest of the day off. They’ll combine the cornstalks with mycelium, a living mushroom root structure, and basically let it grow into any shape mold you want. In this case, bricks.It takes just five days and uses almost no energy and produces no carbon emissions. They’ll even deliver the bricks to you when they’re fresh out of the oven.

3. After you’ve built your summer party pavilion—using compostable mortar, of course—tear it down and take the bricks to a place like Build It Green (conveniently located a mile away from the MoMA PS1 courtyard), which composts enormous amounts of biowaste and gives it to the local Queens community for community gardens and tree planting.

Even though Ecovative has been developing this process for several years, Hy-Fi is the first time they’ve applied to an outdoor architectural structure on this scale, so Benjamin and his partners enlisted the help of Arup on testing to determine how much load each brick can carry to create the right strength and layout.”

“One really nice feature of working with this material is that it’s really lightweight. There’s not a lot of porosity—space in between the bricks—to make a structure that is almost gravity defying and suspended in the air, and of course, the most important thing, is that once they are done being used in the structure they can be returned back to the earth.”

Video by Michael Tyburski.