This story is published in partnership with Engineering for Change, an online resource whose mission is to prepare, educate and activate the international engineering workforce to improve the quality of life of underserved communities around the world.

* * *

Shelling corn by hand is hard, long and boring work, but in some parts of the rural developing world it is the only way to remove the kernels from the cobs for producing corn flour, animal feed or human consumption, saving people hours of labor.

If only everyone had a handy corn sheller. The problem is that commercial shellers are too expensive for most families and cheaper versions, if they’re available in a region at all, are one-size-fits-all. Corn comes in different sizes depending on the variety grown, soil, weather and other conditions and also on the season. A single-sized sheller might not be suitable year round, so customized versions could be useful.

The do-it-yourself corn sheller is a good option, and Engineering for Change has reported on a series of low-cost shellers that upcycle materials like tin cans and PVC pipe. But these can also be a chore to make.

3D printers have become increasingly accessible, and using these tools, my team and I at the Michigan Tech Open Sustainability Technology Lab have developed a solution to the corn sheller problem. This is how to 3D print a customizable corn sheller. It is an example of open-source appropriate technology (or OSAT for short).

By using a low-cost RepRap (self-replicating rapid prototyper) 3D printer, or a solar-powered version of the RepRap, anyone can easily print out the right corn sheller for their needs. This academic paper explains how 3D printing could be a powerful tool for pulling people out of poverty in the developing world. Here we will look at how it can improve the simple corn sheller.

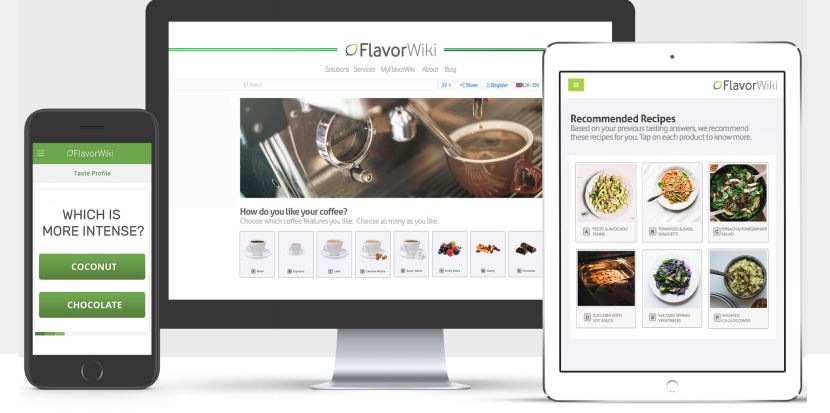

Here you can either use the customizer app or the OpenSCAD to get the right size of sheller for your crop, then print in plastic or metal.

The customizer app enables people without any knowledge of CAD to design their own sheller. Note in the three images above that there is an automatic change in design between the three customized shellers.

As the video above shows, to shell corn by hand you have to crack the cob in half, pick out the first row and then strip off the rest of the kernels. But with a sheller it is much easier.

Being able to quickly and easily change the diameter of the printed corn sheller as shown above again makes it easy to get the best and fastest shelling for your specific corn. Note the blue sheller is about 80 percent of the diameter of the white one and is better at shelling the corn shown.

Joshua Pearce directs Michigan Tech’s Laboratory in Open Sustainability and Technology. Read the original story here.