Microbes. They’re everywhere: our skin, hair and insides teem with trillions of them. It’s impossible to measure, difficult even to estimate, but it is thought that 50 to 90% of the cells in our bodies are guests, other, not ‘us’. Which is weird.

With such proliferation it is little wonder that microbes have been put to work by industrious humans over the past 7,000-odd years: yeasts for brewing and baking, bacteria and molds for culturing yogurt, butter and cheese. For the past hundred years or so we’ve used them to make useful chemicals like citric acid and amino acids, and pharmaceuticals. The deal we’ve struck? We feed them and provide them with conditions favorable to their prospering. In return they multiply, producing useful compounds for us as by-products of their life cycles. Without them, life would go on—we would survive, just—but our existence would be far more pallid, within and without.

In the past people tuned microbes, modifying their genetics to produce certain characteristics, through domestication—just as we’ve done for eons with crops, livestock and pets. However, in the last 20 to 30 years it has become possible to do this through more tailored forms of genetic engineering: synthetic biology has enabled us to rethink manufacturing and design with DNA by using engineering principles to devise and build biological systems that can process information, manipulate chemicals, fabricate materials, produce foods and flavors, and maintain and enhance human health. Indeed, most vitamins that go into packaged foods, such as riboflavin in cereals, are now produced this way.

Yeast colonies arrayed on agar. Image courtesy of Ginkgo Bioworks

Yeast colonies arrayed on agar. Image courtesy of Ginkgo Bioworks

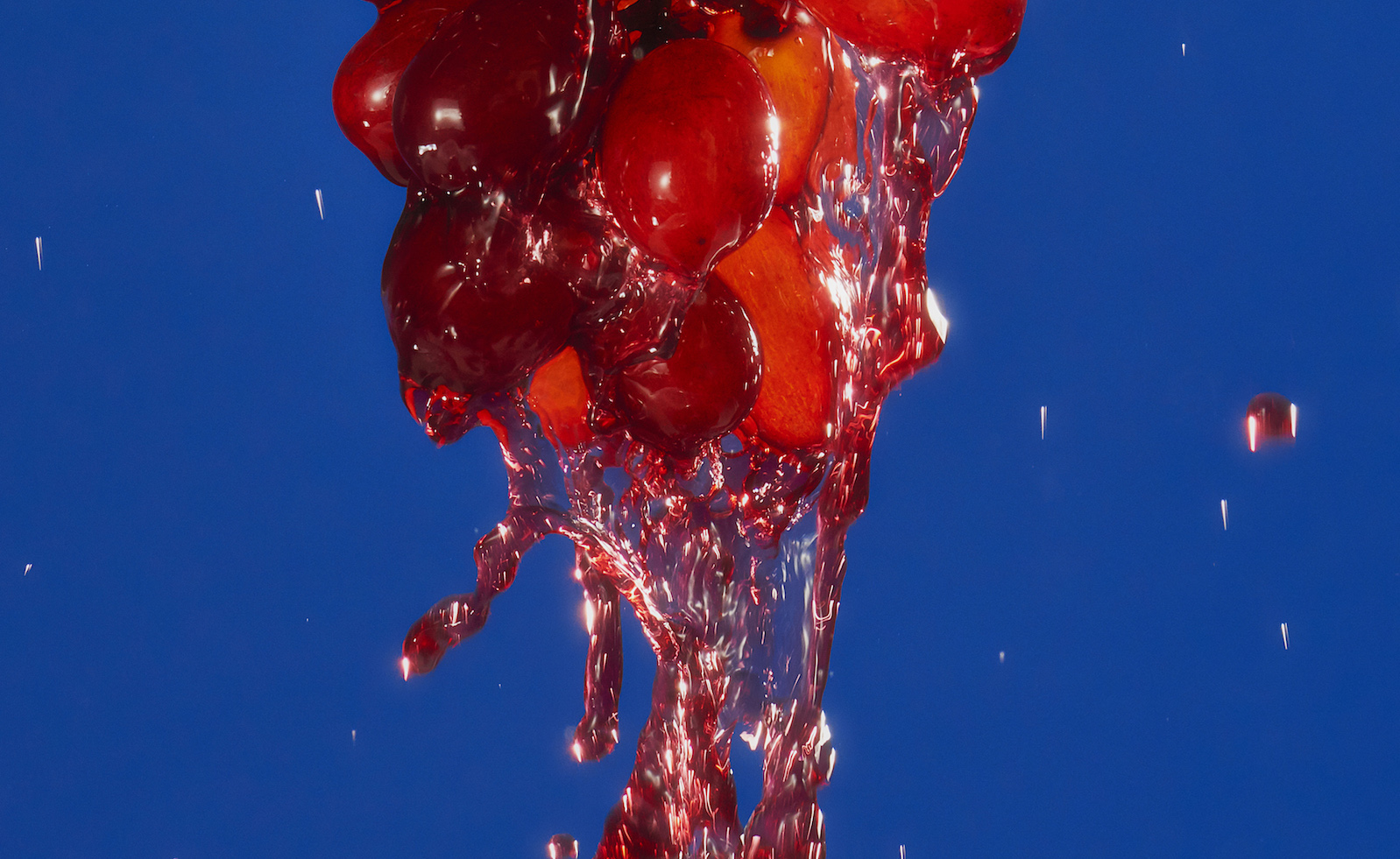

A Rose By Any Other Name

In part of a converted dry dock in Boston, Christina Agapakis, a genetic engineer and Creative Director for Ginkgo Bioworks, talks through some of the ways they use synthetic biology. In one project Gingko have been trying to design and reprogram yeasts to produce a rose-like scent. “To make a rose smell like a rose there are a lot of different molecules that the rose makes,” she explains as she presents two vials that contain the output of two yeast strains that have had their genetics modified in different ways to produce compounds that regular yeasts don’t. They look like the brownish dregs of a beer. While both liquids are distinctively rose-like, one is more floral and the other more bready and sweet: they produce two different components of the rose. One day, Ginkgo hope to be able to develop a single yeast that produces both those major components and tune the yeasts to provide a custom rose blend. “That’s really hard to do! But we’re working on it,” enthuses Agapakis.

Having designed and genetically modified a yeast and found the optimal conditions for its propagation, Ginkgo end up, if all goes to plan, with a highly bespoke solution unique to a customer’s very specific question—a yeast that produces rose-scented compounds or a certain vitamin, for example. With a library of microbes, repurposed and redesigned to serve novel functions, and the understanding of biological mechanisms and pathways that they develop in creating each one, such methods could be incredibly powerful.

The Seeds of Ginkgo

Ginkgo was spun out of an MIT research lab in 2008 by four Ph.D.s and an MIT professor, renowned computer scientist Tom Knight. Knight had become fascinated that the next interesting thing to program and design would be biology and wanted to apply similar things he had seen in the early days of computing in the ‘60s and ‘70s—the development of tools to prototype and test, to model and predict—to help turn biology into a more design-led discipline. Since then, Ginkgo has been combining biological insights from the past 40 years with computational muscle and advanced robotics—that have become available in the past 10—to design microbes to ‘brew’ smells, flavors and nutritional ingredients with unprecedented precision and in more sustainable ways.

Ginkgo’s Design Foundry

Although it may not look like one, Ginkgo is, in essence, a design firm. At the heart of all they do are three processes—designing, building, testing—but instead of working with metal, glass, concrete or plastic, their materials are biological, living organisms. Keen to avoid controversies that can badger the acceptance of novel technologies by the public—scare stories of “grey goo” that spread when nanotechnology first entered public consciousness or uncertainty around GMO, for example—part of Christina’s role is to communicate the company’s work, their products, their story, and engage in how Ginkgo and the public think critically about new products. “We don’t make a technology we design a product, ” explains Christina. “At the highest level you want to produce something. You want yeast that’s different from just ‘normal’ yeast.”

When Ginkgo’s clients come to them with a question––can you make us a vitamin, a flavor, an enzyme for making a cheese, or something multi-functional that can, for example, produce flavor and aid preservation––they look first to nature. “We look at how biology solves that problem in other organisms; the enzymes, the proteins, the biochemistry, and then the genetics.” Ginkgo’s organism designers use computational analysis and simulations to find examples of organisms that produce, say, enzymes that might be suitable for the job, understand the pathways that produce them and the genes that code for them, and then design DNA sequences to ‘insert’ into yeasts to try to modify their function. “For any enzyme we’re interested in there’s now tons of sequences on public databases we can draw from.” This is one key development of the past 10-odd years that have made this sort of work possible. Another is that the creation and replication of those DNA sequences—carried out by another company—is now much cheaper.

Extrapolation Factory set up a pop-up futuristic bio-product assembly line inside the foundry.

Extrapolation Factory set up a pop-up futuristic bio-product assembly line inside the foundry.

For each project the designers, mirroring evolution, come up with many versions: tens of thousands of DNA sequences, yeast strains and datasets to explore and test. Advancements in the automation and centralization of sample processing has driven down the cost of rapid prototyping and made organism design at this scale possible. Once the DNA has been inserted into the yeast cells, done by startling them with a chemical or electricity, the task is to identify which picked up the DNA and verify the insertion happened at the right time and place. Like evolution, there are lots of failures and dead-ends (maybe one millionth of a billion cells pick up the DNA and incorporate it into their genome). Most often when things go wrong, nothing happens. It’s just normal yeast, still. Ginkgo see how the engineered strains differ from the wild, unengineered strains by cracking the yeast cells open and analyzing the chemicals therein.

Once they’ve found combinations of DNA and yeast strains that do what they want, they look for conditions for the yeast that will allow them to optimally extract lots of the desired final product. Ginkgo’s design foundry contains fumehoods full of banks of mini-reactors and robotic arms that can monitor a wide range of fermentation variables, such as how pH or oxygen levels change as the cells grow and when the yeast needs to be fed more sugar. “We want to keep them happy because they’re working hard for us. But the conditions are particular for each yeast, they all have their preferences. In the past, this would have been carried out by a human pulling out samples of each fermentation to check its progress, but now a robot can do that all night long,” Agapakis explains.

Bioart & Design

Before joining Ginkgo in 2015, Christina’s completed her Ph.D. at Harvard and then worked on numerous bioart projects that nurtured her interest in how artworks can help ask questions about the potential of microbes: where are they, what’s their role in everyday life, what do we think of them, and how can they be a more welcome companion? The 2013 Selfmade project she co-created with Norwegian artist Sissel Tolaas involved a series of ‘microbial sketches’ that reflected the microbial landscape of different people in cheese-form: cheeses were crafted from starter cultures sampled from the belly button of food writer Michael Pollan and the tears of artist Olafur Eliasson, among other sources. The entrance to Ginkgo’s offices harbors a further example that can prompt such questions: a Winogradsky panel that comprises two sheets of glass between which soil and silt is thickly sandwiched. With the passage of time, microbes in the substrate grow producing dynamic, evolving patterns that recall Monet’s water lilies: subtly graduated patchworks of colors that, although abstract, suggest underlying order. When one digs further into what Ginkgo does, it becomes clear how Agapakis’ interests have led her here.

Future Foods?

“It’s about how can we use microbes to improve flavors or enhance character. The technology will help us to better understand and work with bacteria and yeasts to make good food in the future,” Christina reflects. What remains to be seen is how the public will respond to such foods: although ‘brewed’ products, like the rose scents, are likely to avoid GMO-certification because the genetically-modified parts of their manufacture—the yeast cells—are removed, numerous ethical questions remain. Concerns about whether the technology is intrinsically problematic revolve around whether something is violated when biological systems, whole organisms even, that aren’t found in nature are created to fulfill roles defined by humans: does life, if it is considered to have it in the first place, lose its sacredness if it is designed? If we are dealing with microbes producing flavors or vitamins then many would consider not, but what happens when synthetic biology involves organisms closer on the phylogenetic tree to human life?

Microbes on a petri dish. Photo courtesy of Ginkgo Bioworks

Microbes on a petri dish. Photo courtesy of Ginkgo Bioworks

Moreover, there are the extrinsic considerations; the potential risks and benefits. Aside from the danger of deliberate misuse of the technology to create pathogens or toxins that can be weaponized, there is the possibility of organisms inadvertently escaping, and evolving and adapting to new environments in ways unforeseen by their creators. One lesson that the study of traditional biology teaches us is that living things and their interactions are complex, often more so than we initially perceive. We must be mindful of not being over-confident that we can control and predict the behavior of artificially created organisms, and understand their risks. Furthermore, with synthetic biology set to offer hugely powerful ways of producing food, fuel and medicines, thinking about who controls and owns it, and ensuring they do so in line with its potentially wide-reaching social and environmental impact, is vital. Regulation, thus far, has been light, largely because many of these issues have been considered in debates surrounding existing genetic engineering technologies, but as more products are made in this way—hacking microbes in ways unfamiliar to most—it seems clear that the roles of people like Agapakis will become more critical in promoting discussions in the public domain about how such technologies work, and why and when they should or shouldn’t be used.

Understandably, she is keen to focus on the expansive beneficial potential of Ginkgo’s work in producing functionalized, customized probiotics and tastier food. “Maybe we make new starter cultures for cheeses; there are so many enzymes involved in ripening cheese, breaking down the oils and making all the flavors: people intuitively manipulated them without knowing that bacteria existed, so what new tastes are possible now that we understand the biology, chemistry and role of human interaction?” Moreover, could we engineer the tastes of things we don’t have any more, such as rebreeding the taste back into chicken? Now that seems like a prospect that could get the public talking about synthetic biology, and that many would be willing to get behind.