From Dieter Rams to Apple the prevailing aesthetic for consumer electronics is a sleek plastic box. Recent Royal College of Art graduate Jeongwon Ji has another idea of what those ubiquitous elements of our lives might look like. Instead of streamlined mass-produced casings, she asks whether they might be expressive and tactile, with subtle differences between the millions of units produced. Her bio-plastic made from the shells of the invasive Chinese Mitten Crab does just that.

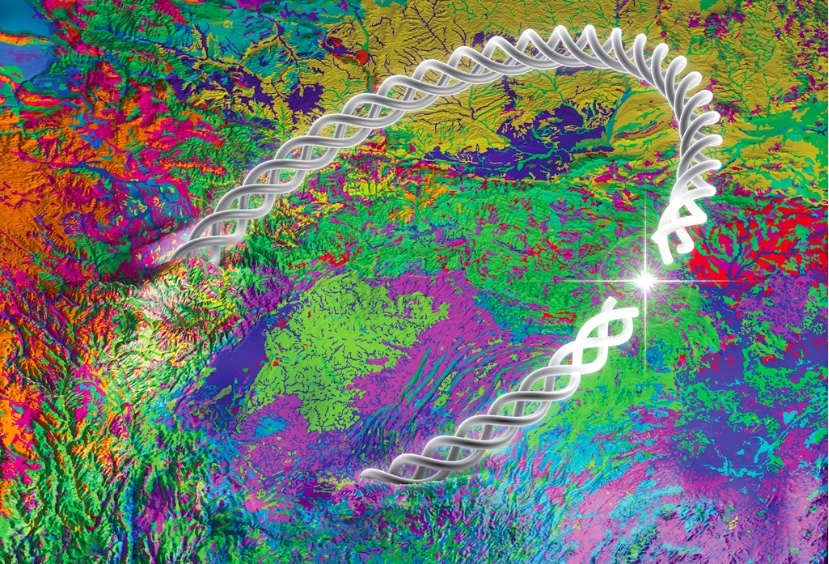

While the aesthetics of consumer electronics are certainly under investigation here, that is just the tip of the iceberg. Ji is challenging the established paradigms for materials, production and working conditions in large-scale manufacturing. Interested in local resources that would allow for higher quality materials by saving on shipping costs she experimented with a range of organic waste. The chitin polymer extracted from crab shells won out for its combination of both strength and flexibility. Sourcing it from an invasive species of crab in the River Thames was an added bonus.

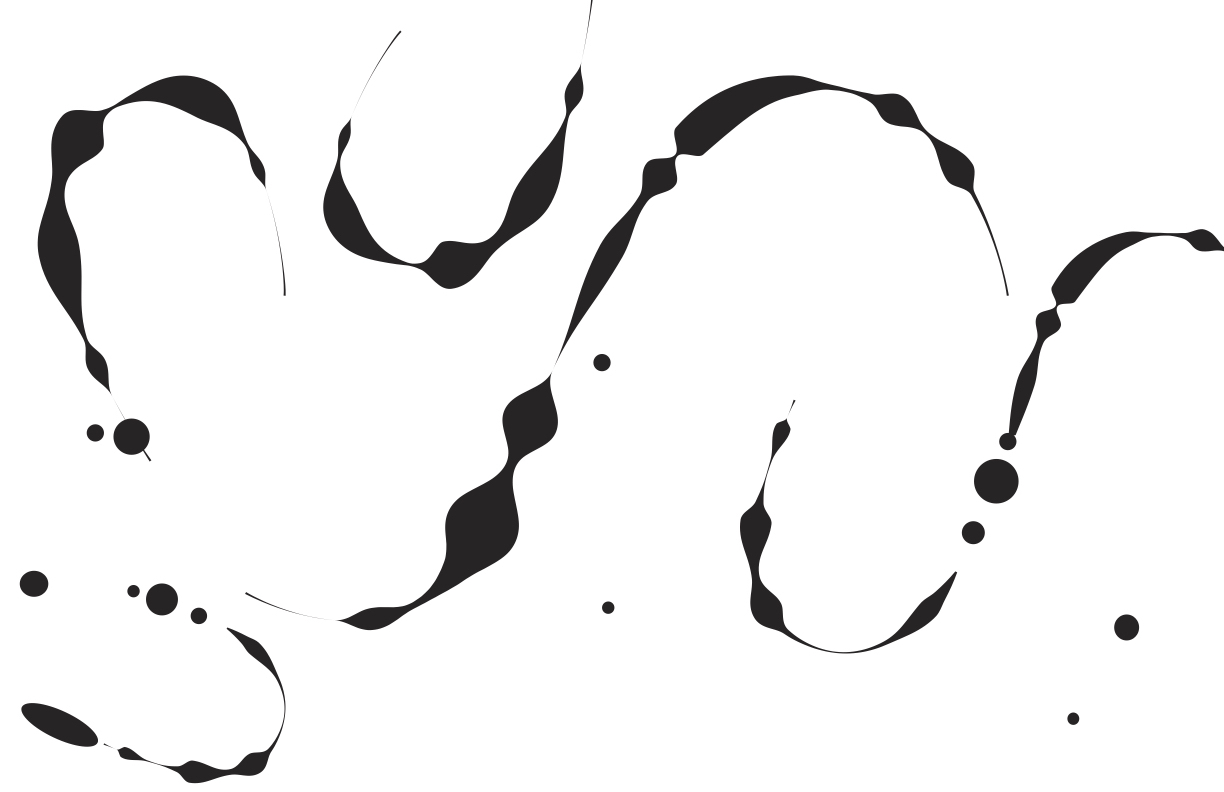

Engineering a new bio-plastic without a material science background and a strict rule against toxic ingredients had its challenges. Thoroughly documented failures allowed Ji to analyze her results and make pragmatic decisions as she moved forward. Her non-toxic production process is not only safe for factory workers, but also creates novel organic shapes for the casings due to the slow cure time.

To think that some day your new iPhone might not just provide safe, valuable jobs but also do your local river good.