During the early 20th century, automats featured cooks behind-the-scenes, making food in standardized units that were then served through a vending machine. This fall, in one of San Francisco’s priciest neighborhoods, a new robotic, gourmet burger restaurant called Creator will reverse this model: A machine will prep and cook custom orders, not behind the scenes but in the dining room, while “concierges” and “burger experts” consult with visitors to help them identify and order their favorite flavor pairings. The menu consist of discrete components—burgers, sides like fries or grain salads and drinks—designed to mix and match flavors like umeboshi plum, fennel seed, chipotle sea salt or sunflower seed tahini in a variety of ways. Another of the eatery’s innovations is that it will sell these made-to-order burgers, some designed by posh chefs, for only about $6 a pop. The most surprising thing about Creator is not how sci-fi the robotics are, but how human the hospitality is.

Creator isn’t the first to automate its kitchen—from coffeeshops to quinoa bowl cafes, Flippy the burger flipper to the sandwich-fixing Bistrobot, and a sci-fi bot barista, others are doing it too—but it may be the first to fully automate its kitchen. Creator’s kitchen is eight years in the making and unlike traditional professional restaurant kitchens, the machine was designed as a tool that is flexible and mobile enough to be rolled around and plugged in. Funded by the likes of Google Ventures, the concept has been brought to life by a team of engineers, roboticists, designers, chefs and restaurateurs from places like Tesla, NASA and Chez Panisse. It’s not just a kitchen; it turns the entire restaurant into a chef’s table.

Most people are thrilled at, and slightly fearful of, the robot, but at Creator the robot isn’t actually the point. The point is what the robot allows the restaurant to do—things that are potentially industry-shaking. This precise culinary tool can do what humans can’t: determine the ideal grill time of each patty, grind the meat in a way that humans can’t. Creator is using robotics not to replicate and replace human labor, but to enable a number of human-friendly goals including: serving fully customizable meals and the freshest food possible (meat is ground, seasoned and cooked to order); creating less menial jobs for humans; and diverting operating budget towards better ingredients with the hope of making quality food more accessible and democratic. In a delicious reversal, it is using robots to put the emphasis back on hospitality and the human.

“Our approach is, we want to be shepherds around how technology and humans interact. We designed Creator for people to experience automation in a positive way,” explains Culinary Lead and Experience Designer David Bordow, a mechanical engineer who worked in the kitchen at Chez Panisse and studied product design at Stanford University.

Right now, there are two 14-foot-long burger-making robots, engineered and fabricated almost entirely in-house from some 600 unique parts, including 20 computers, 50 actuator mechanisms and 350 sensors. “We refer to it as a device, but it’s actually many devices, each one designed to do one specific task extremely well,” Bordow says. No part of the machines is anthropomorphic. There is no moment of peering into the uncanny valley of a face designed in our own image and feeling a frisson of recognition. Designed by Berkeley and Oslo-based Per Selvaag, the machine is constructed from a curvaceous blond laminated wood base with glass cabinets and cylinders that showcase the color, freshness and beauty of the ingredients, making them major elements of the interior design.

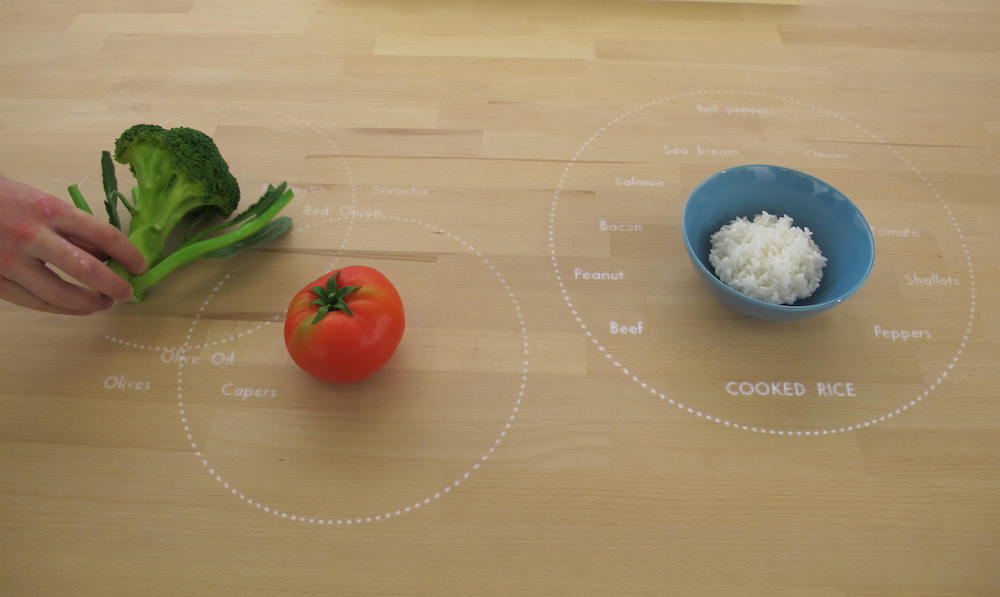

Once an order is placed, air pressure nudges a locally baked La Boulangerie brioche roll through a tube where it is sliced, toasted and buttered to order and placed on a compostable leaf-shaped clamshell to-go container. Along the way, tomatoes, pickles and onions will be sliced to within a millimeter of accuracy, lettuce freshly shredded and cheese grated onto the burger. The robot grinds the meat—a blend of hormone-free, pasture-raised chuck and brisket—using a vertical grinding method. Not considered practicable until now, the technique was theorized by three-Michelin-star chef Heston Blumenthal, whose own burgers cost upwards of $20 each. It makes the burger tenderer and juicier because the vertical strands align with the bite but creates such a loosely packed patty that it would fall apart in the human hand. Thermal sensors and an algorithm time each patty’s grilling, and a copper conveyor “belt”, made up of articulated tiles, allows each order to travel at a different pace along the line. The process takes about five minutes. Each Creator (cost: under $1 million) prepares up to 120 burgers an hour, a number that should go up to 400 with time.

Before a customer walks in the door, humans are visible through Creator’s glazed storefront facilitating machines and advising guests. So, while there are humans behind a counter, taking out the trash and manning the fryer, most of them are on the dining room floor. One of the most surprising things about Creator may be how tasty the food is. But the most surprising thing is the answer Creator suggests to a big, simple question: Will a robotic restaurant change how we feel about hospitality in the future? The answer may be that it won’t.