A vision of Jetsons-age access to an unending menu of dining options at the push of a button is firmly rooted in our imaginations. Now, we have the wonder of 3D food printers producing architectural shapes in chocolate, pancake batter and pizza dough on command. Beyond the shine of a new kitchen gadget, what is the real promise of 3D food printing and what are the challenges of getting there?

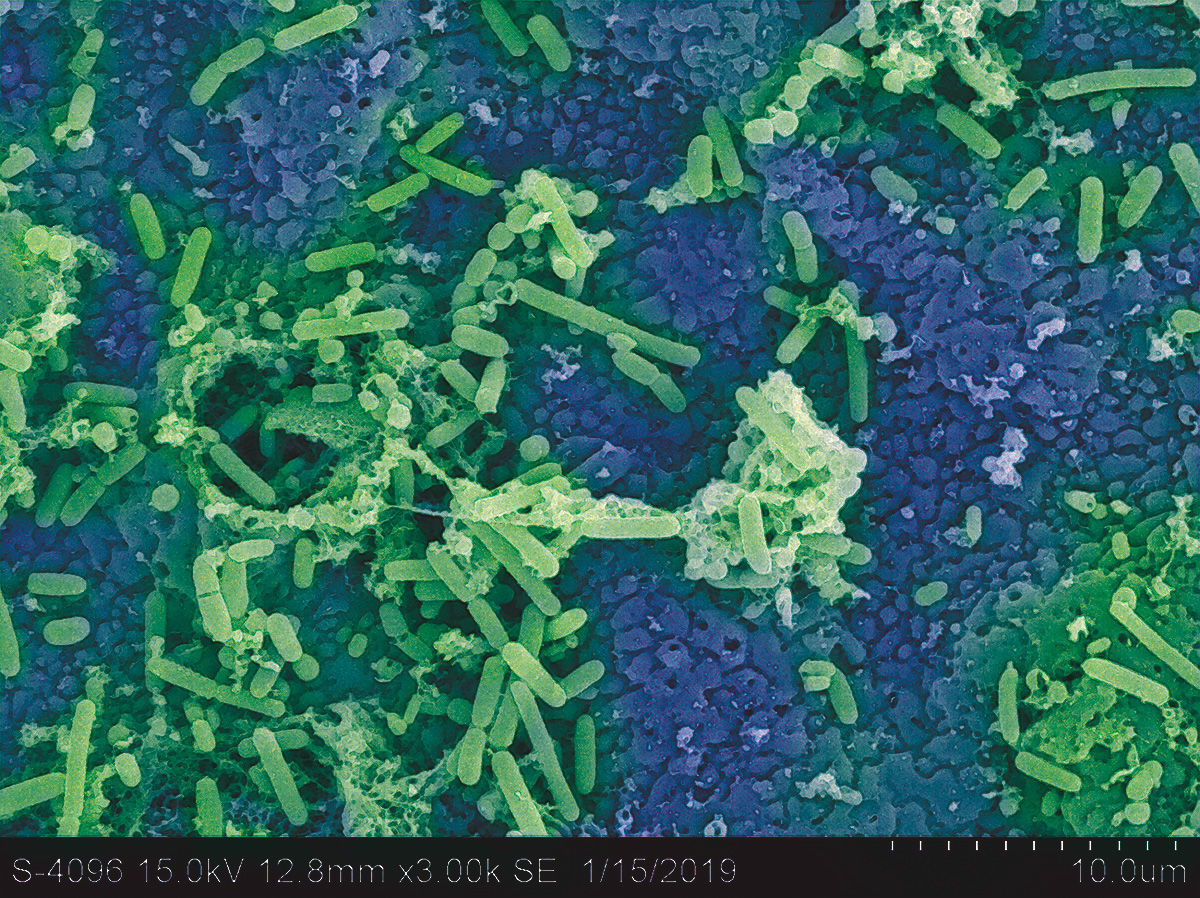

Last week, 150 researchers, designers, industrialists and manufacturers gathered in The Netherlands for the world’s first 3D food printing conference to answer some of these questions. With the technology in its most nascent stages, the stakeholders in this world of hackers, gastronomes and academics are experimenting with both the hardware and applications for 3D food printing. Food safety researchers mingled with representatives from Pepsi Co. Materials scientists chatted with machine makers about process. But can 3D food printing learn from the mistakes of Makerbot and become an integral appliance in the kitchen of the future?

WHY PRINT FOOD?

Among the topics up for discussion was the fundamental question of purpose: Why 3D print food? And for whom? What emerged from the day’s talks were five pillars for 3D food printing:

Design Freedom

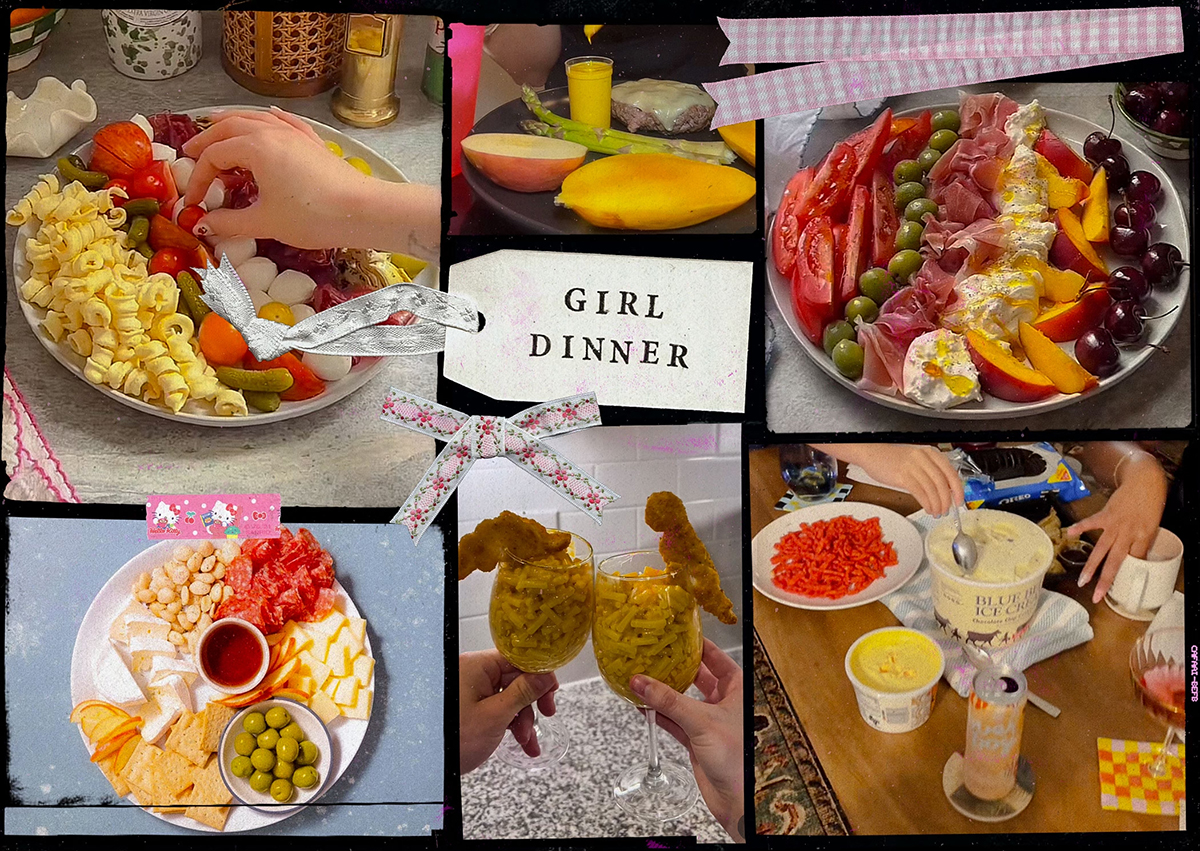

In it’s current state, 3D printed food is an aesthetic consideration and an opportunity for personalization—print a pancake in the shape of your dog, print yourself as a marzipan cake topper or print sugar in hypercolor architectural shapes. But once the delight wears off, is there a place for 3D food printing beyond the beautiful?

New Ingredients

3D food printers can become a vehicle for introducing new foods to the population. With food scarcity on the horizon, new sources for protein and nutrients are being explored. Perhaps a insect burger would be less daunting if you could print it in a friendly shape. But as Jelle Groot, an analyst at Rabobank, pointed out in his introductory talk, smaller food manufacturers are already introducing these ingredients in grocery stores. Dutch grocery store Jumbo started selling the Insecta Burger and Buggy snacks—mealworms, buffalo worms and waxworm larvae in pepper and salt flavors—on their shelves last fall.

Social Experience

Until we can find a place for the 3D food printer in our personal kitchens, the technology will be relegated to the realm of novelty attraction at restaurants, grocery stores or maker fairs. Even the machines on view at the conference, of which there were very few, were not consistent nor useful for every day food preparation.

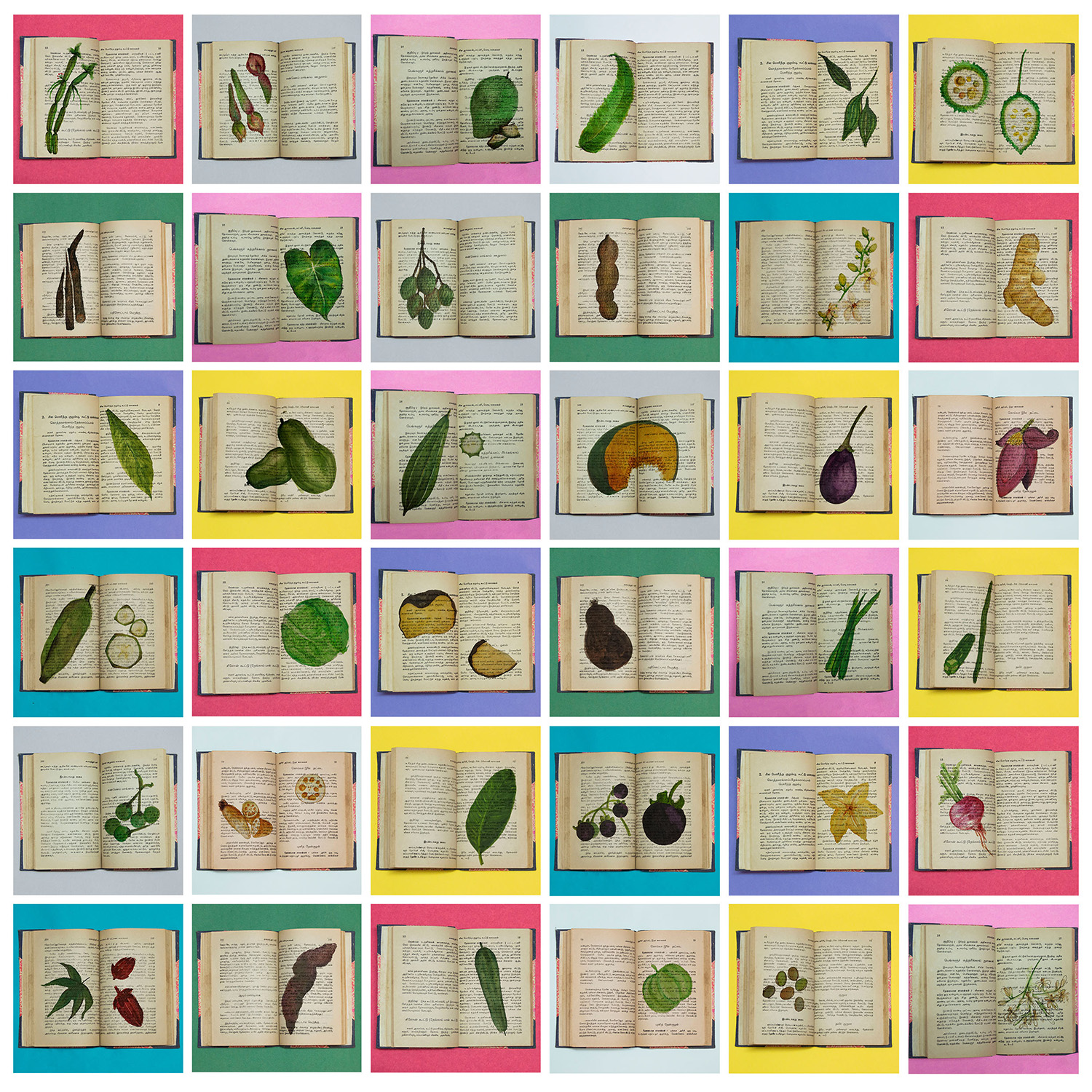

Decentralized Production

If the technology could develop to a sophistication where it became an essential appliance for cooking food—perhaps replacing microwaves or other fad appliances—it could offer an opportunity for more efficient and decentralized form of production. Ingredients could be delivered in food cartridges, avoiding wasteful trends in food packaging and perhaps cutting down on food waste itself. The pasta maker Barilla held a 3D pasta printing contest last year imagining a future where one could extrude pasta in bespoke shapes in your own home. One winner’s design is a rose-shaped pasta that “blooms” in boiling water. Another was spherical with craters to “improve the interaction between pasta and sauces.” What’s more, you could print the exact amount of pasta you would need, no more and no less.

Food for the Quantified Self

In an age of fitness trackers and feedback loops monitoring health and wellness, 3D food printers have the ability to deliver personalized and balanced doses of vitamins and nutrients in the form of an edible printed product. Not only would the technology be able to deliver individualized meals, but it would be able to do so at scale creating real opportunities in health care, extreme environments (like military outposts) and elder care.

CASE STUDIES FOR 3D FOOD PRINTING

Elder Care

Launched in 2014, PERFORMANCE is a program of personalized food for the elderly. Nursing home patients face a number of challenges related to eating—many have difficulties chewing and swallowing in addition to having a wide range of nutritional needs. PERFORMANCE aims to address this through 3D food printing individually tailored meals. 3D food printing allows for nutritionists to personalize meals around the food parameters of vitamins, calories, portion size, micronutrients and hardness. The program is currently being field tested at two nursing homes working with six food items: chicken, pork, broccoli, cauliflower, pasta and potatoes but aims to expand the ingredients in the near future.

Industrial Production

Since 2006, FoodJet has manufactured food printers for industrial production. Using a “smart” printing head with processing capabilities, there are over 100 FoodJet machines installed and in use around the world. Manufacturers are using the machines to increase accuracy, produce branded or seasonal products and create the “impossible” i.e. tempered chocolate printed inside a cookie. Although there are capabilities to create multiple layers and high resolution with his machines, one interesting insight that CEO Pascal de Grood shared is that the industry is more interested in high efficiency rather than high resolution. And the average number of layers being printed? One. Not a single company has used the machines to print more than a single layer.

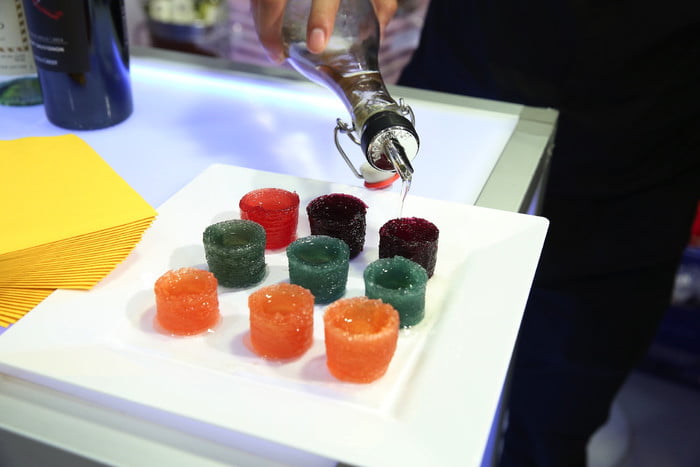

Digital Gastronomy

Barcelona-based Robots in Gastronomy works with chefs to develop new experiences in eating with bespoke 3D printing machines and software to deliver specific technology solutions to the most innovative professional kitchens. CTO Luis Fraguada explained that the research and design group has, “the goal of creating the next generation of culinary appliances.” Working with Michelin-starred chef Paco Morales, RIG created a new platform for parametric associative eating, doing away with knives and forks and creating foods that delivered both flavor and function.

CHALLENGES

While there are innovations occurring in the field, the technology for 3D food printing is still elementary. At this point, it is unclear whether there will real applications for 3D food printing in the home in the near future. Currently, the technology is slow and the resolution for consumer machines could basically be achieved with a pastry bag and a fine pastry tube. The real revolution for 3D food printing will occur when 3D food printers move beyond the novel to become an essential kitchen appliance with the ability to combine foods—not just extrude single ingredients—and execute some basic preparation and cooking techniques in a high performance environment. On the slow road to relevancy, fans of 3D food printing are creating new communities around the technology with recipe banks, research in diversifying texture in 3D printed food, and launching crowdfunding campaigns to keep the public engaged and ready. “Forget how food is now,” Fraguada urged in his presentation. “Let’s imagine entirely new modes of gastronomy.”