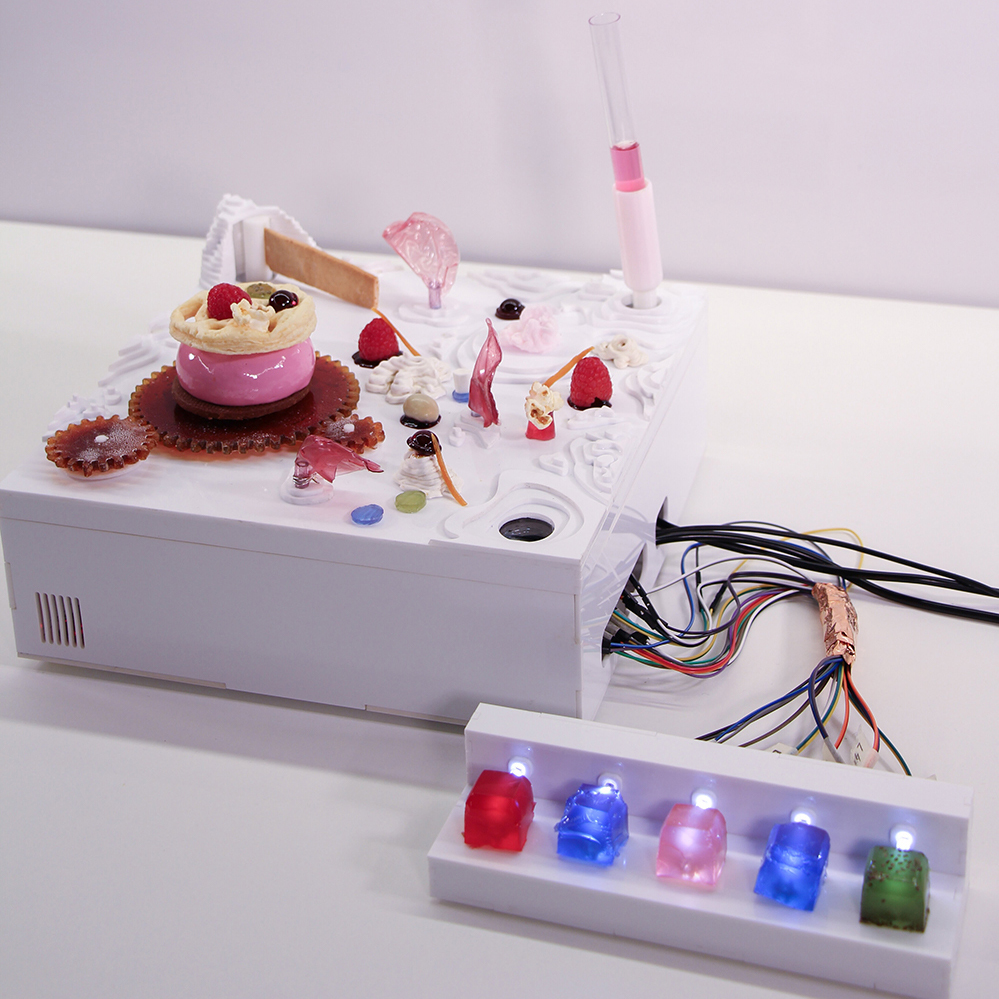

Update January 7, 2014: The Sugar Lab has launched the Chef Jet and Chef Jet Pro, the first professionally certified, kitchen-ready 3D food printers, at CES 2014. The Chef Jet (~$5000) will print single color confections while the Chef Jet Pro (~$10,000) will be able to print in full-color. The printers work with sugar and chocolate and will be available through 3D Systems this year.

Los Angeles-based architectural design team Kyle and Liz von Hasseln have a penchant for complex geometries and tasty sweets. The couple recently launched The Sugar Lab, a service for 3D printing a range of sculptural, sugar-based objects in service of the sweet life. Cake toppers, sugar cubes, pie lattices, grapefruit sweeteners and centerpieces are all fair game.

While completing a masters in architecture from SCI-Arc, they decided to try their hand at 3D printing a birthday cake for a friend. Although the initial idea was unsuccessful, they did manage to top a birthday cupcake with their friend’s name lovingly 3D printed in a script of sugar. Using a mixture of water and alcohol, The Sugar Lab has created a process to reliably construct small scale sugar structures. As they tell it, “the process is fundamentally similar to other 3D printing applications, we’ve just optimized the process for resolution and strength with sugar, rather than with a standard 3D printing material.”

MOLD had an opportunity to speak with Liz about their design process in a short Q+A below:

MOLD: What are some of the most unusual requests you’ve had?

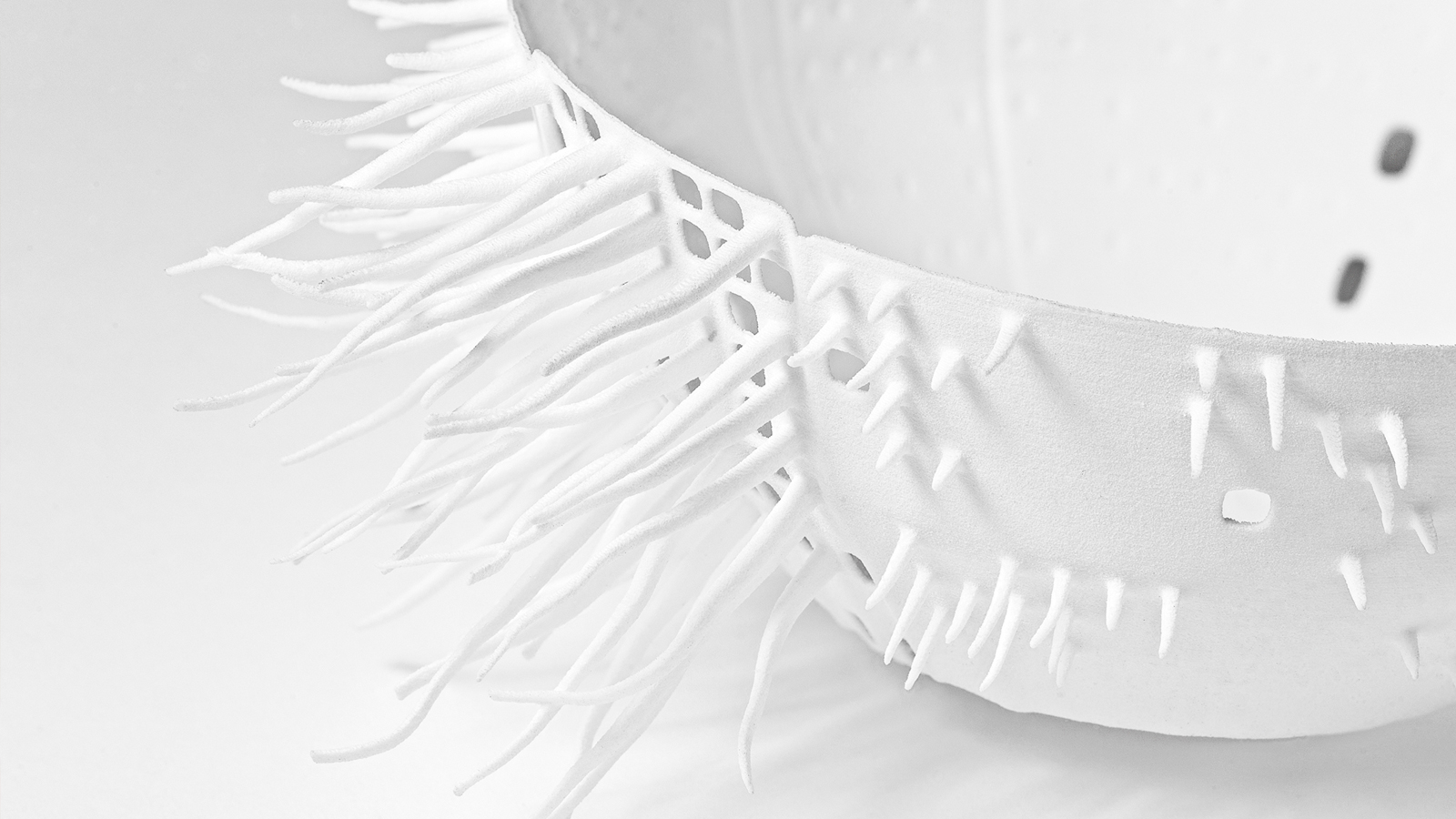

The Sugar Lab: Probably the most exciting project we’ve tackled yet is the one that we’re working on currently—we’re very excited to be collaborating with some seriously talented cake artists at Charm City Cakes in Hollywood to design a four-tiered wedding cake with a 3D printed sugar cakestand, and 3D printed sugar-tiers supporting cake tiers. It will be a traditional cake silhouette in which sugar plays anything but a traditional role. That’s an exciting part of 3D printing sugar for us—transforming sugar into a structural, sculptural medium that can start to define the form of the food instead of the other way around, and even to support it structurally.

What are the challenges of working with a material like sugar?

There definitely are design limitations. Sugar isn’t as strong as 3D printed plastic. For example, prints that are too top heavy could break under their own weight. Our backgrounds in architecture have helped us to develop design instincts for integrating structural and facade elements into single 3D printed sugar sculptures. There are also more secondary design elements related to 3D printing sugar like color, taste and surface texture that come into focus when you work with sugar. People have expectations about what food looks, tastes and feels like, and its really important to hit those notes, otherwise you have a cool design, but it might not look like dessert.

What type of 3D printer do you use? Did you have to “hack” it to print sugar?

If you’ve ever made frosting and left the mixing bowl in the sink overnight, you know that moistened sugar gets quite hard. That’s the underlying concept of 3D printing with sugar. We use a mixture of water and alcohol, applied very precisely in a layer-wise manner, to selectively wet and harden the sugar substrate. The process is fundamentally similar to other 3D printing applications, we’ve just optimized the process for resolution and strength with sugar, rather than with a standard 3D printing material.

How have your backgrounds in architecture helped you think about The Sugar Lab?

Kyle and I both have backgrounds in molecular biology, but about five years ago we decided to transition to architecture, and we graduated from SCI_arc this past fall with Masters of Architecture. SCI_arc makes it a point to embrace emerging technologies as design tools, and that institutional stance meant that we were exposed to a lot of really cool technology during our time there, and we were encouraged to use it in novel ways. Throughout graduate school both Kyle and I were fascinated by free form fabrication in general, and unorthodox 3D printing configurations and materials in particular. Our graduate thesis, although it had nothing to do with sugar, centered on the development of a novel fabrication system. Our shared curiosity for the range and utility of 3D printing definitely contributed to our interest in applying the technology to the genre of food.

Images Courtesy of The Sugar Lab